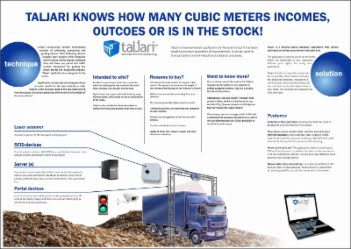

Taljari is accurate database solution for measuring cubic meters

Taljari is a new kind of tool for measuring cubic meters. It´s use is accurate, fast and affordable and you dont have to make costly investments. Beside it is a transferable measuring system. Word ”Taljari” is a Finnish old profession name for ”Tally Clerk”. ”Taljari” was a person to record all the incoming or outgoin charges from a ship.

What is Taljari?

Taljari has developed especially for measuring cubic meters of bulk material directly form the truck or trailer. It can be used to measure wooden chips, soil and other bulk materials.

It is a databased solution which uses sensors like laser scanner and RFID-technology.

The Taljari solution is primarily intended to measure cubic meters. It can be used to measure incoming, used in production and staying in stock material amounts. It is a real-time system and with it you can easily control the stream of material for production.

Reasons to buy it?

- It is fast and accurate system to measure cubic meters

- It can be moved to another location if needed

- It has an interface to determine the weight by using moisture measuring

- Enables the raw material process management

- Very low purchase and operating costs compared with vehicle scales

- You can use the solution from any network-connected terminal. Username assign permissions

- You can share measuring results with your customers/transport companies eg.

- It can be widely customized

Features of Taljari solution

Contents are in their own tabs, such as incoming, outgoing, measuring screamed materials, the usage of raw material and the amount in stock.

You can search information from the database. Search parameters can be eg. date, supplier, the origin, type of raw material, transport company, rejected loads, the amount, the amount used, the available quantity…

Import, export, share or save. Data is stored on the server, where it will remain for many years. You can also save the searching results/reports or sent those to a third party. Data can also be transferred to the automation system.

Content of delivery

– Movable portal with laser scanner (measurement), the RFID antenna (to identification of vehicles), a camera (visual assessment of the load), traffic light (to control the traffic) and the system equipment in the cabinet (RFID unit, power supplies, wiring, heating etc).

– Server to process the data. Browser-based solution can be used by workstations

– Touch Screen Workstation (printing waybills). The driver selects variable information eg. the origin, type of raw material…

– Scanners to raw material conveyors if needed

– Installation, implementation, training and maintenance services.

More information & Sales

Call +358 5 225 5000 for more information or fill the contact form below